The one area on internet forums where you see more problems and situations that can't be figured out is with custom brake systems.

For such a simple system in theory, it's absolutely amazing how complicated a brake system actually is. It's even left automotive engineers scratching their heads a time or two.

Now, do you think you have the know-how to mix and match parts?

That's why it's so important to go with a proven system.

Factory parts are specifically designed to work together. That's why if you use a brake system off a particular car, you want to use the whole system. Not parts or pieces. One way to reduce the engineering required is to use as many components as you can from the same donor car.

Aftermarket brakes are usually the way to go. You can usually get a system that is designed for your car.

When you go shopping for brakes, it's a good idea to buy a system instead of trying to combine the parts yourself because of the complexity and importance of the brakes.

I like making stuff myself. Brackets, making mounts to put engines in cars that never came with them, custom body work, etc. The one area that I do spend money on for a premade system is the brakes system. It takes the guesswork out, eliminates a million problems, and is usually cheaper in the long run. Plus, I'm putting my life on the line with my brakes.

Want to save money? Hang your clothes out instead of drying them, don't eat out as much, go to the basic package on satellite instead of premium, etc. You'll make up the money you spent on brakes real quick. You're not putting your life on the line with these things. You are with your brakes. This is one area you don't scrimp on.

What kind of system?

Disc/drum systems with a dual master cylinder are pretty much the standard anymore. There are also disc/disc setups, but those are usually reserved for very serious braking like on a road course. Unless you plan on seeing some track time, it's kind of overkill.

Power brakes vs. manual.

Manual brakes give you good pedal "feel". In a lighter car they work great. They can also work well in a larger vehicle, but the effort will be greater.

Power brakes work better in a larger vehicle due to less effort to stop. However, it can be more complex.

One problem people run into when changing between the two is they forget the pedal ratio. This can cause troubles that can be hard to diagnose.

Pedal ratios are the difference between the distance from the pivot point of the pedal to where the pushrod attaches and the distance from the pushrod attachment point to the pad on the pedal.

Look at a pedal in a vehicle that was offered with both manual and power brakes. There are usually two different holes that the pushrod of the master cylinder can attach to. If you change from manual to power, you have to change the hole the pushrod attaches to.

Common pedal ratios for a manual system are 7:1 or 8:1, and 4:1 or 5:1 for power systems.

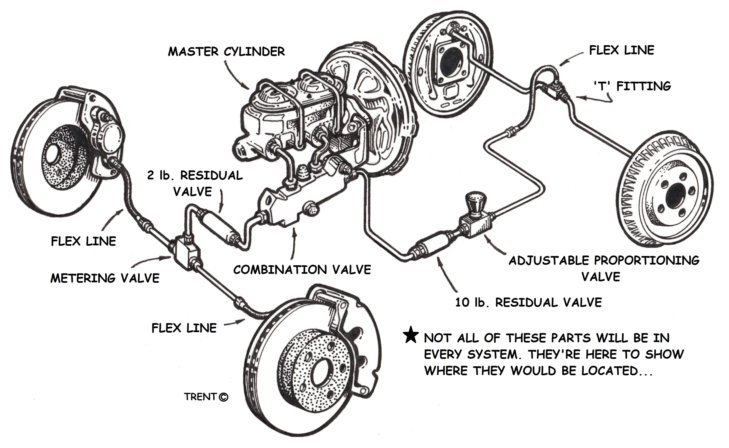

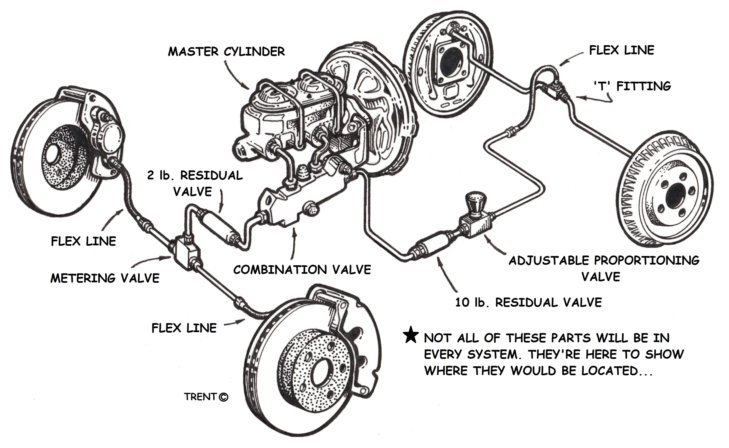

Ok, lets look at the different things you will find in a typical brake system.

MASTER CYLINDER

At the least in a brake system, change to a dual reservoir master cylinder. The master cylinder needs to match your braking system. Otherwise you can have all sorts of problems. A drum/drum system needs a drum/drum master cylinder, a disc/drum system needs a disc/drum master cylinder, a disc/disc needs a disc/disc master cylinder.

The size needs to match the system you have. While there is too much information about all the models of cars out there to cover here, it's easy to find out what you need by simply calling one of the brake companies listed below.

Also, to answer your questions about what kind of master cylinder you need look at this:

COMBINATION VALVE

The combination valve does four things:

1. It does the job of a METERING VALVE. It keeps pressure from the discs until you have 40 psi, then it lets the pressure go to them. It does this so the rear brakes can partially overcome their return springs and take up the slack. It keeps the front brakes from grabbing under very low pedal pressures, like when you are on ice or snow so you don't slide. Once you are over 40 psi line pressure there is no benefit to having this valve.

2. It acts as a PROPORTIONING VALVE. It sets front to rear braking ratio. That is, it lets the front brakes have a little more pressure than the rears. This is to make the brakes stop at the same time, with the fronts locking up just ahead of the rears. Your front brakes do most of the stopping.

3. It does the job of a RESIDUAL PRESSURE VALVE. It keeps 10 PSI in the drum brake lines. Don't worry about brake drag, it takes roughly 75 PSI for the shoes to overcome the return springs and make contact with the drum. This does two things.

First it keeps the shoes close to the drum so you don't have as much travel. This prevents having to pump the pedal twice to make the brakes work.

Second, it is possible for the seals in the wheel cylinder to suck in air when the pedal is released suddenly. They only seal when there is pressure against them. When you let off suddenly, it can cause a vacuum against them and it can suck in air. Air = Spongy

4. It also has a WARNING SWITCH. It senses any differences in front to rear pressure and warns of a leak by turning on a brake warning light on the dash.

2 lb. RESIDUAL VALVE

These valves are used if you have disc brakes and your master cylinder is lower than your calipers, like when it's under the floor. The valves keep the fluid in the calipers from siphoning back into the master cylinder when you let up on the brakes. If your master cylinder isn't that low or is slightly above the calipers, it can still happen if you're parked on a hill!

If you ever have to press on the brake pedal twice to get a hard pedal, you need them. If in doubt, just put them in.

Don't worry if you aren't sure if your master cylinder has them or not. Just put them in. They are not cumulative and it won't hurt to have two.

10 lb. RESIDUAL VALVE

These valves are for drum brakes. It keeps 10 PSI in the drum brake lines. Don't worry about brake drag, it takes roughly 75 PSI for the shoes to overcome the return springs and make contact with the drum. This does two things.

First it keeps the shoes close to the drum so you don't have as much travel. This prevents having to pump the pedal twice to make the brakes work.

Second, it is possible for the seals in the wheel cylinder to suck in air when the pedal is released suddenly. They only seal when there is pressure against them. When you let off suddenly, it can cause a vacuum against them and it can suck in air. Air = Spongy

Don't worry if you aren't sure if your master cylinder has them or not. Just put them in. They are not cumulative and it won't hurt to have two.

METERING VALVE

This valve works on your front brakes. It keeps pressure from the discs until you have 40 psi, then it lets the pressure go to them. It does this so the rear brakes can partially overcome their return springs and take up the slack. It keeps the front brakes from grabbing under very low pedal pressures, like when you are on ice or snow so you don't slide. Once you are over 40 psi line pressure there is no benefit to having this valve.

ADJUSTABLE PROPORTIONING VALVE

Most stock systems use a combination valve or a proportioning valve

However, unless your car has an almost identical weight ratio front to back like the donor car, you could be in trouble. The rear brakes could lock up before the fronts if your rear end is lighter than the donors.

There's an old saying: "The end that slides is the end that steers."

You don't want your rear end coming around on you and spinning you out.

So, some people will ditch the combination valve or a proportioning valve in favor of an adjustable proportioning valve. Most all aftermarket brake companies have them. They go inline to your back brakes. Turning the knob adjusts how much braking power goes to your rear. You adjust it so the front brakes lock up just before your rear ones do. Simple and safe.

Dig this page? Please let other hotrodders know! Here's how.Would you prefer to share this page with others by linking to it?